Driving Retail Experiences with Supply Chain

I spent the better part of last week at Shoptalk18. Increasingly, it’s evident that customer experience cannot be discussed without the mention of supply chain or a function related to the supply chain. I’ve stated previously that the supply chain is no longer only a driver of operating leverage but also the catalyst for differentiated customer experiences. The assertion is increasingly proving out during discussions with retailers, eCommerce, and brands. Here are some noteworthy observations as I think/parse through everything I heard, saw, and discussed at Shoptalk:

Walmart seems to be experimenting to figure out the role of (existing) brick/mortar for their customer experience. From in-store pick up stations and curb-side pick up, to last-mile delivery, Walmart is taking bolds risks to figure out how to deliver value to customers in the way they want it. If a customer doesn’t want to walk around the store, that’s ok, they can order ahead and walk inside to grab their product from a large, cylindrical kiosk. Furthermore, the work flow around curb side pickup seems to be evolving. The retailer is experimenting with smaller physical outlets for curb side (and might I assume delivery) — not just rely on existing large retail buildings. This could afford a better footprint for automation — it wouldn’t make sense to add additional structures if there’s not a meaningful reason to do so — there’s tens-of-thousands of square footage already built out. I suspect that these smaller structures will be “magical” on the inside with automated pick/pack, in/outside parcel relay, intelligent inventory, streamline last-mile delivery processes, and more. The experience might end up being akin to a car wash in the long-run — low human touch, high standardization, and near round-the-clock availability.

Test Walmart pickup facilities

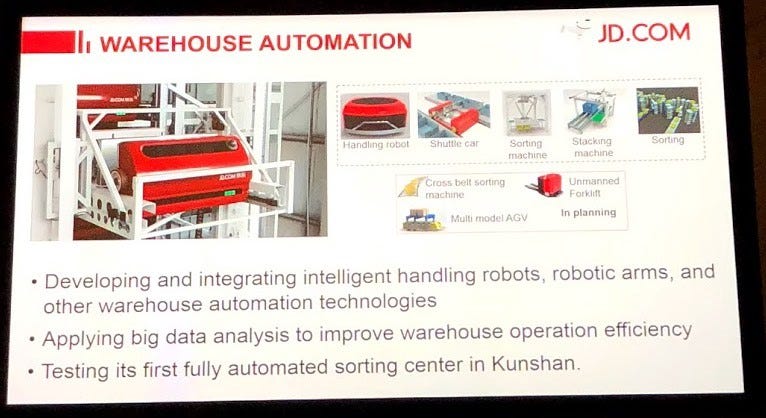

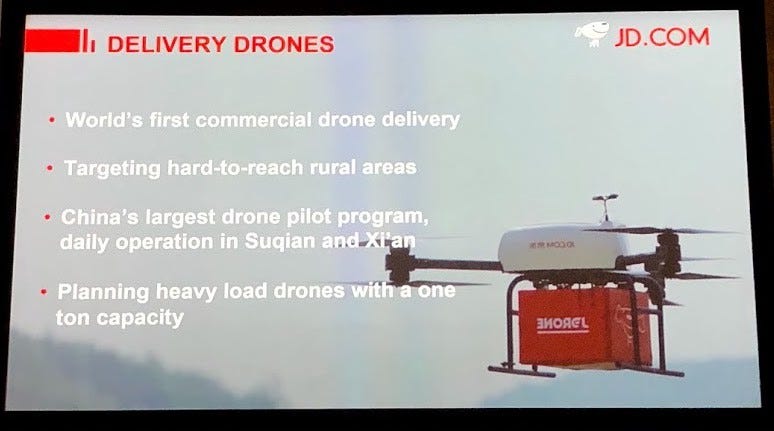

JD.com is using the Amazon playbook and it will capture supply chain spend. One of the last sessions I attended was with Dr. Hui Cheng of JD.com. The massive takeaway was that JD is building it’s own internal supply chain platform and will sell it’s “dog food” to the masses at an opportune time (like Amazon/AWS). JD realizes that logistics is the driver of great eCommerce and is working on automating last mile, warehouse robotics, and autonomous drones and delivery bots. I suspect that JD might be further along than we realize and might be a great leading indicator as to what works/what doesn’t and inform us of broader trends that we can embrace broadly across global supply chains. The competitive risk is also not to be discounted — although, the timing of such a broad-based effort remains to be seen.

JD.com warehouse automation strategy

JD.com autonomous delivery vehicles

JD.com delivery drone strategy

Grocers and related haven’t been asleep at the wheel — they’re surprisingly tech-forward. Make no bones about it, Kroger, Peapod, Bright Farms, Amazon, and Walmart showed off not just R&D efforts but technologies they have deployed in/around their supply chain. Some things the industry as a whole is trying to drive: full transparency from food production through to shipping and handing; automation of high-risk/repeatable process from farm through fulfillment; rethinking agriculture footprint to small/local from large/remote farms to improve product quality; leveraging existing data to improve shelf-data and stock management process. We’re spending A LOT of time in/around the ag-chain this year from farming through to grocery fulfillment. We would love to hear from you if you’re building a company that can address any number of the problems/opportunities in addressing and fulfilling the rising food demand we face over the next 20–30 years.

Bright Farms changing the nature of produce sales

Kroger’s data-driven provenance, customer intelligence, and stock management efforts

Hope to see you at Shoptalk19, next year!